Portable Stainless Steel Glass Bead Blasting, Unimech Engineers Private Limited ID 23201924948

The most common type of media used in bead blasting is small, spherical particles of glass that are shot with air pressure to remove coatings or polish the surface. Other types of media used in bead blasting include silicone carbide and stainless steel beads. Overall, glass bead blasting produces the smoothest finish to the surface.

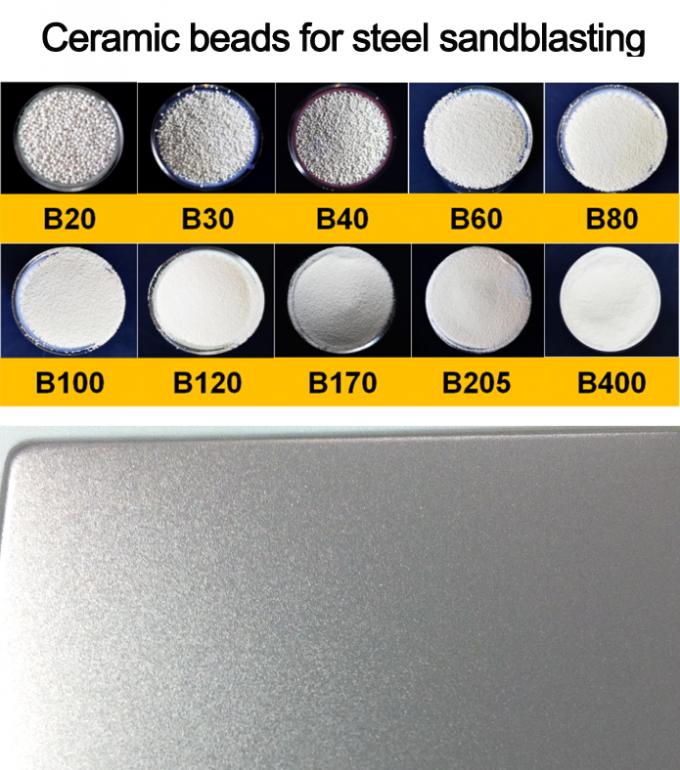

Stainless Steel Finish B400 Ceramic Beads Blasting Media packed in 25kgs 55lbs barrels

Glass bead blasting produces a clean, bright, peened, satin finish, without dimensional change of the cast stainless steel parts. They can be recycled approximately 30 times. Chemically inert and environmentally friendly, glass bead blasting is an acceptable method of cleaning or surface finishing for components after stainless steel casting.

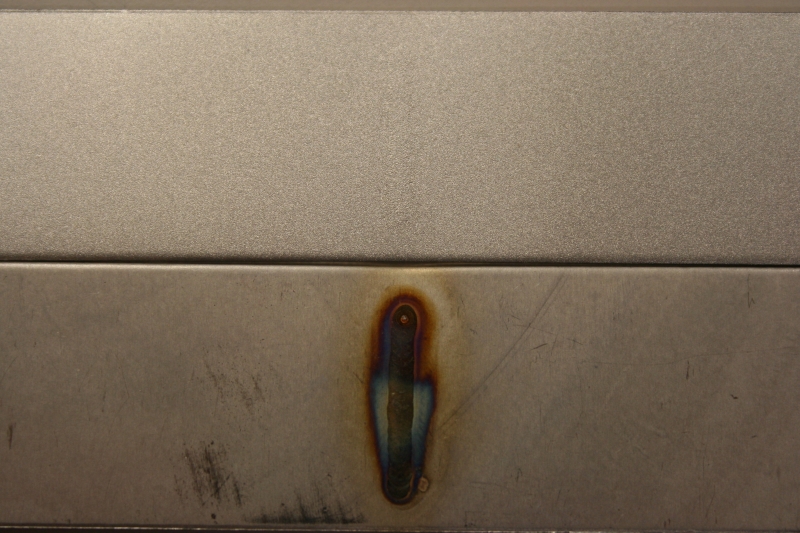

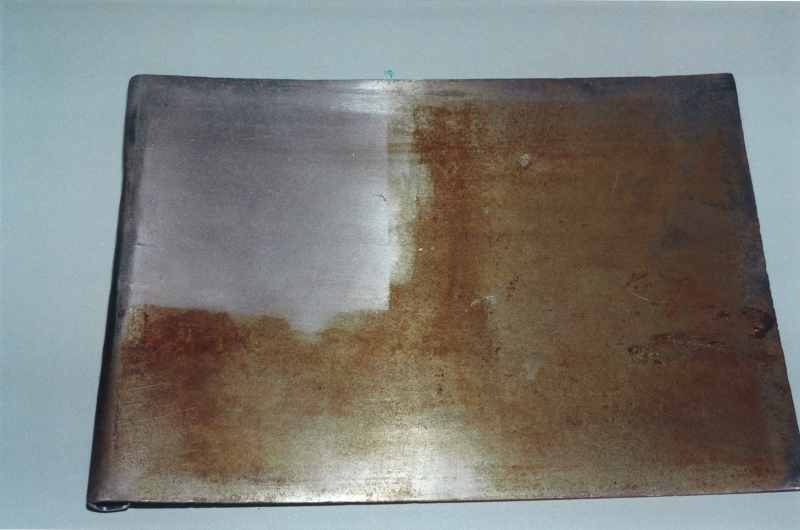

Blasting of stainless steel

Our Team Provides A Wide Range Of Shapes, Sizes & Compositions of Abrasives. Call Today! SurfacePrep Has Glass Bead Blasting Media Available to Meet Your Surface Finishing Needs.

Portable Stainless Steel Glass Bead Blasting, Unimech Engineers Private Limited ID 23201924948

Bead blasting aluminum is also an excellent choice for preparing surfaces for anodizing, as the process effectively removes dirt, grease, and other contaminants that could interfere with the anodizing process. Glass bead finish on stainless steel. A glass bead finish on stainless steel uses delicate beads during the bead blasting process.

120/150/180/220 Grit Glass Bead Blasting Media

Common mesh sizes for glass bead blasting include 50-70, 60 -80, 70-100, 120 - 200. The fastest cleaning glass bead is typically 60-100 mesh. The right size blast media will ultimately depend on your individual application. Glass Bead Blasting Equipment Glass bead is meant to be reused and so will require specific equipment.

Stainless Steel Glass Bead Blasting Service at best price in Bengaluru

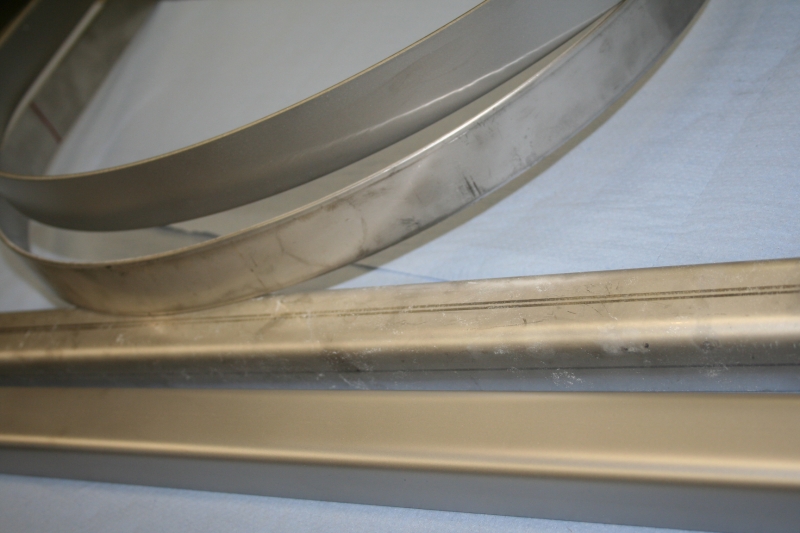

Bead Blast Finish Stainless Steels. Bead Blast finish was produced by the impact of a hard, inert medium onto the surface result in a non-directional, uniform matt surface with a soft satin reflection and low reflectivity. Bead Blast finish provides a clean, consistent, streak-free finish, making it extremely suitable for panel-to-panel matching.

Glass Bead Blasting, Glass Beading or Bead Blasting Secondary Services Inc. Buffalo, NY

A bead blast finish aims to leave a workpiece surface clean, smooth, and shiny. While this is the ideal result, a poor bead blast process can lead to the exact opposite.. Glass bead diameter can be classified as "fine" or "coarse", or sized by "grit". Common grits are 40-60, 60-100, 100-170, and 170-235. The bigger the.

Portable Stainless Steel Glass Bead Blasting, Unimech Engineers Private Limited ID 23201924948

Bead blasting involves the release of fine glass or steel beads at high pressure to finish a component's surface. During the process, a high-pressured tool shoots bead-shaped media towards the surface. This process occurs in a well-monitored bead blasting cabinet, leaving a shiny, smooth, clean surface.

Blasting of stainless steel

Bead-blasted stainless steel is a type of stainless steel that has a matte, non-reflective finish that is achieved through a process called bead blasting. This finish is often called a "satin finish," but it is not the same as the brushed finish of satin stainless steel. Bead blasting is a surface finishing process adopting a high-pressured.

Bead Blasted Finish Stainless Steel Stanch Bead Blasting Stainless Steel Supplier

Glass bead blasting involves using spherical glass media to give a uniform finish on components surfaces at high pressure. On the other hand, the traditional sandblasting technique uses silica sand to confer surface finish on the material.. It is a versatile process that works with metals like stainless steel, aluminum, and cast iron. Thus.

Everything You Should Know About Bead Blasting How to clean metal, Beads, Metal

For this reason blast finishes should not be applied to stainless steel thinner than 0.4 mm. To avoid product distortion on thin sections, blasting on both sides should be considered. Specifying bead blasted finishes for stainless steel. Bead blasted finishes for stainless steels are not covered in BS EN 10088-2 as a special finish type, (Table 6).

Bead Blasting Stainless Steel Epoxy Systems Blasting & Coating

After glass bead blasting on stainless steel frame. Glass bead blasting is commonly used for food-grade stainless steel applications. It polishes the stainless steel for a uniform finish and removes surface impurities.

Blasting of stainless steel

Bead blasting is a metal finishing process that creates a uniform, shiny, and clean surface on your part. In this process, a bead blaster shoots bead-shaped.

Glass Bead Blasting for Stainless Steel Castings INVESTMENT CASTING

The five main benefits of bead blasting for stainless steel are: It provides a clean and consistent, streak-free finish, even on complex shaped fabrications. Ensures that the surfaces of the fabrication are free from lines, grooves, pits or divots which could encourage the growth of micro biological organisms.

Stainless Steel Gate Glass Bead Finish close up » Miller Sandblasting

For a satin type finish when blasting stainless steel there are three primary blast medias that are commonly used. First is glass bead, which is generally the most popular. Glass bead will not profile the surface of your product but will create a satin like finish making it one of the best choices in relation to the finish it will achieve.

Glass Bead Blasting Jantz Canada

In addition, glass media is recyclable, making it cost-effective and eco-friendly. You can also use it on most metals, including stainless steel. It is important to note there are some important considerations. Glass bead blasting needs to be done in a temperature-controlled environment. Hot and humid locations can clump the media, making it.